For Dummies v1.0 “Doctors are just the same as lawyers, the only difference is that lawyers merely rob you, whereas doctors rob you and kill you, too.”This article has been produced anonymously by multiple authors in an attempt to educate people who have received or are considering the possibility of getting silicone “body art” implants — ie. not from a medical professional in the surgical field. This article should be in no way misinterpreted as a “how-to” guideline for artists, and in no way merits the practice of 3d art implant work as safe or even viable. Implants installed by anyone other than a doctor (not that professionally installed implants are safe either) are extremely dangerous, and all individuals participating in this practice do so at their own risk. Silicone has been in use as a medical implant material in various forms since the 1950s. Silicone gel has been the subject of numerous lawsuits for its use as a filler in breast implants, resulting in the withdrawal from use in implantation, as well as the bankruptcy of the Dow Corning corporation. These regulations are currently being reconsidered in light of new “cohesive gel” materials and strong scientific evidence that the conditions alleged in of most of the lawsuits were unrelated to the implant material. Silicone gel is not the subject of this article. The implants addressed here are made with silicone elastomer which is a widely used and accepted material throughout the medical field. Common medical implants composed of silicone elastomer include, but are not limited to cheek implants, chin implants, pectoral implants, artificial heart valves, breast implant bags, and coatings used on pacemakers.

First let’s get some basic classification terms for silicone implant elastomers straight, as confusion of these terms has caused some problems and possibly false accusations in the past. Industrial grade silicone: Any of a multitude of silicone products used for a huge array of non-medical applications. Some are harmless and possibly even biocompatible, but some definitely have toxic ingredients. While it may be feasible to get a perfectly good result implanting industrial materials, it could just as easily end in disaster or death. If your artist can’t find something at least referred to commercially as a medical material they shouldn’t be offering the service in the first place, and are likely to hurt people as they apparently have done none of their homework on the subject. Medical grade silicone: This is a general term used with varying definitions, often used to reference silicones that get used for tubing and sheeting type applications in the medical field, but that are not used inside the body. This usually refers to at least food grade, which means they are cleared by the FDA to be in direct contact with food items. Or possibly FDA USP class VI, which refers to a test battery that verifies the biocompatibility of a material. The links at the end of this article allow further education on USP classifications as well as other related topics. Most silicones referred to under this term would be unlikely to cause problems if implanted, but they are possibly not certified for it. Implant grade silicone: Silicone companies generally do not refer to their implant materials with this title. They use two titles which may vary from company to company, but at last check there were only a small handful of companies willing to even touch this application. Short term: These are materials that are generally identical to long term use materials, except that they are approved for use in the body for a limited period of time, usually 30 or 90 days. This is mostly for liability reasons, as there is only so much that commonly goes wrong with things that are in the body for that long. Short term materials are usually batch tested for cytotoxicity and trace elements as well as other testing depending on the manufacturer. Long term: This is what all professional medical silicone implant parts are made from. These materials are approved for use in the human body for an indefinite period of time. It is probable that they may sometimes differ from short term materials in price only, which is frequently ten times more than an identical short term material. The price is almost certainly the result of the massive liability insurance required to field a product for this application. If you are familiar with Dow Corning going bankrupt over boobs, you can fully appreciate why. Shore or Durometer: Silicones come in a variety of hardnesses defined in Shore A. Implant silicones range between a hardness of 7 shore A (very soft) and 80 shore A (hard). 3d art implants are generally in the 7 to 30 range. For impact resistance, softer materials are preferred.

Advantages Smaller incision: Because of their flexibility, silicone implants can usually be compressed through a significantly smaller opening than a rigid part of the same shape. This reduces the size of the resulting scar, and reduces the chance of severing nerves in the skin with the incision. Impact resistance: 3d art implants can be prone to getting hit or crushed. This can be extremely painful, especially if the implant is made from a rigid material such as PTFE or stainless steel. This pain is from the skin on top of the implant being pinched between the implant and the external object, as well as force trauma to the underlying tissue. The softness of silicone allows it to deform under pressure and absorb impacts, making it a much more comfortable material. This also diminishes the possibility of implant loss from tissue trauma if extreme forces are applied to the implant site. Encapsulation: The body cannot bond with silicone or grow into it, so it builds a pocket of scar tissue around it. This is an advantage only in that it allows for easy removal, if one should decide they no longer want the implant. Disadvantages Stickiness: Silicone has a sticky surface texture. This is a problem because it will take on outside contaminants much more readily than other materials, which makes it far more likely to have problems with surface contamination. Exposure to open air after washing and sterilization should be kept to an absolute minimum. This unfortunately means that infection is more likely with silicone than with less sticky materials like PTFE and steel, because practitioners are usually unable to offer the cleanroom type environment that would be necessary to completely eliminate this factor. Even under rigorous laboratory cleaning protocols, surface contamination is always present, even from contact with the bags parts are packaged in. Chemical retention: Silicone may be “non-porous” but it can soak up outside chemicals on a molecular level, so exposure to anything toxic such as disinfectant soaks (biocompatible surgical scrubs can be an exception) and chemiclaving should be absolutely avoided. Exposure to toxic chemicals will result in a toxic implant. Cut resistance: Silicone, especially in softer durometers, offers very little cut or tear resistance. This is not usually a problem once encapsulated within the body, but care must be taken not to damage the implant by over-stressing it during insertion or using inappropriate tools against it that may damage or tear it. This is especially important during removal as it is easy to tear or cut off portions of the implant in the removal effort, and care must be taken not to leave parts of the implant behind in the body.

It is highly unlikely that an implant being offered by an implant “artist” was manufactured in a professional certified implant manufacturing facility. This brings its own risk factors on top of the risks presented by the procedure itself. Silicone becomes a 3d art implant usually in one of two ways.

Advantages: Carving block (if acquired directly from a reputable source) is a sort of guaranteed clean material, as it has been created in cleanroom conditions and is a pure, certified material. Disadvantages: The blocks must be carved to shape with a scalpel or other similarly sharp cutting tool, which can be extremely difficult, especially for the novice. Silicone does not lend itself to carving and a smooth surface texture has proven impossible to achieve. Care must be taken not to leave any incomplete cuts or flaps on the part as these can retain contaminants after cleaning as well as creating weak spots that will easily tear. Think of a windshield with a crack — once the crack has started, with minimal stress on the structure, it will continue until it has reached the other side. Incomplete cuts in carving blocks will split in a similar manner if the material is stretched. 2. Molded: A practitioner may acquire silicone materials in a liquid form. These liquids (usually in an A and B two component kit) are then mixed and delivered into a mold where they cure to a solid state. This process is similar to the manner in which professional medical implants are often made. Advantages: If done properly this process can result in a smooth precise form impossible to achieve when carving from block material. Disadvantages: Because the molding process is not being performed in a certified professional medical manufacturing environment there is no guarantee of the cleanliness of the processing methods. If not made with expensive air filtration systems and an absolute attention to cleanliness, parts will retain whatever materials (dust, organic materials, cleaning agents, and so on) they are exposed to. Even if the silicone materials used are long term implant materials this can still result in an unsafe implant. Attention to cleanliness in the mold is the most important factor, as any debris or material of any sort left on the surface of the mold cavity will be molded directly into the surface of the implant where it will be in contact with the body. Cleanliness throughout this entire process is extremely important. Manufacturing of molds that can meet these cleanliness standards is also difficult and expensive, especially if metal molds are to be used.

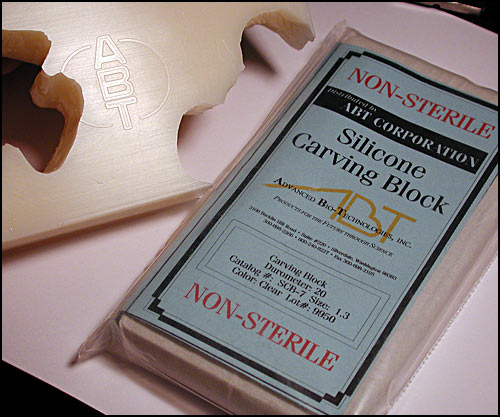

Now that we have covered the basics of silicone implants, lets get on to more specific incidents and problems that have arisen over the last few years. Raised text = Industrial material: This is a popular rumor that has spread in the form of accusations against practitioners that they were using industrial grade materials. On more than one occasion implants have been removed by people other than those who installed them and at this time raised text has been discovered on the flat surface of the back of the implant. The situations in which these implants are sometimes removed, are because of discomfort or outright failure of the body to accept the implant, which leaves the recipient upset and looking for a reason for this failure. Upon observation of this labeling text, individuals have speculated that this is an indication that the material is of industrial origin. The following is an example of long term implant grade silicone blocks with raised text identifying the manufacturer:

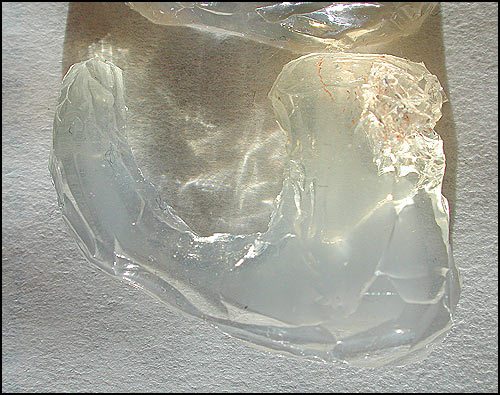

While material degradation is possible, it is highly unlikely especially in the time frame presented in most of these cases. Use of industrial materials may cause the body to break down around the implant, but the implant itself would actually be less likely to break down, as industrial materials are often differentiated by additives that make them more environmentally stable, which usually means they will be less likely to break down in the body. The “cracking and crumbling” is much more likely cutting and tearing. As mentioned previously, low durometer silicones cut and tear easily. The amount of force exerted and particular tools used for these removals easily breaks up the silicone resulting in a crumbled appearance, but the silicone has not degraded. Once again, degradation is possible, but unlikely. Further analyzation and testing would be necessary to verify actual degradation, which has not been documented yet. Below is a photo of a perfectly healthy implant removed for aesthetic reasons. The damage is from scalpel and forceps, and is only that which was necessary to remove the implant with these tools. Larger more complex designs frequently exhibit much more extensive damage, especially if the person doing the removal is not careful or experienced with the material.

It is worth noting that while other individuals have exhibited little or no bleeding during procedures like this and have ended up with perfectly healthy implants, lack of bleeding should be interpreted as a warning signal. Good blood circulation is necessary to heal a wound and deal with the contamination that comes with these sorts of surgeries. Without sufficient circulation infections can spread, and contaminants remain in the area continuing to damage the tissue. Traction/Friction: Areas of the body that stretch or flex can be problematic. Implants that are forced to move frequently inside of the body are more likely to cause tissue damage, and possibly permanent tissue recession, secondary to chronic inflammation. One particular case involved a long segmented design placed vertically in the abdomen. When the abdomen was contracted it pressed painfully against the abdominal muscles. Over its 9 month life it wore away against the abdominal muscles causing pain that has persisted years after the implant was removed.

ANATOMY: Location can be critical to the level of safety with a given implant. Proximity to vital organs can be directly associated with time until death (window of time for medical intervention) if a dangerous infection sets in. There are many dangerous areas that should be avoided when choosing the placement of an “art” implant. Joints are dangerous because of the amount of movement as well as the fact that nerves, critical blood vessels, and lymph channels are often closest to the surface in these areas. Nervous and lymphatic anatomy should always be researched for a given area, and all nerves and lymph nodes/channels should be avoided. The outside (peripheral) areas of the body over the top of major muscle masses are generally the safest areas for this sort of work, although in reality there is no truly safe place for an implant. WARNING: 3d art implants are a very dangerous practice. They should not be confused with the risk levels associated with tattoos or piercings. If you are not accustomed to the idea of permanent bodily harm, and the possibility of death, you need to stick with piercings and tattoos. While the possibility of death is relatively slim if medical attention is immediately available and the individuals involved are cautious (practices like motorcycle racing are much more likely to kill you), the possibility of permanent (and painful) tissue damage is very real. Infections around the implant can occur even decades after implantation. Do not expect the person installing your implant to have done any amount of research to qualify them for this practice, and thoroughly research the subject yourself. There are no professionals in this field, and the practice is questionably legal at best in most locations. Many of the individuals installing these implants are seriously undereducated in medical practice and specific anatomy relevant to the subject, to say nothing of general sterilization and cross contamination issues. Again, this is far more dangerous than commercially available body modification. Doctors in many countries will lose their license to practice if they participate in these activities, so the people left doing these procedures are often grossly underqualified. It is highly recommended that you establish communication with a sympathetic medical professional before you proceed, who will be able to aid you if problems arise. There is a good possibility of the need for antibiotics or surgical attention, and if these things are not available to you, you will likely end up in an emergency room with a group of unsympathetic doctors, who often use brutal methods to remove the implant, and you may be hospitalized for days. The physical and mental trauma from this sort of experience (to say nothing of the bill) can be devastating.

IAM members click here to comment on or discuss this article

Online presentation copyright © 2005 Shannon Larratt and BMEzine.com. Requests to republish must be confirmed in writing. For bibliographical purposes this article was first published online September 26th, 2005 by BMEZINE.COM in La Paz, BCS, Mexico. |