Development and Updates by Jesse Jarrell, March 31 2006

The idea of attaching something to the human body by means of an implanted magnet of some sort is likely older than I am, and before I began the initial experiments with Steve Haworth and Todd Huffman, the idea had been tossed around by myself and others around me for years. Implanted magnetic attachment units already existed in use for denture attachment, and cochlear implants (hearing impairment solution). Samppa in Finland had installed some sort of magnet in his forearm, but it did not appear to bear much weight. I’m sure many other experiments had been done elsewhere, but I had no knowledge of them. A year or two earlier a friend of Steve and I, Grinder Smith, had told us about an iron filing that had been temporarily lodged in his finger while he was employed at a stereo shop. In this shop they had both magnetized and demagnetized speaker magnets. Grinder found that he could tell the difference between the two from sensation created by the iron filing moving in his finger. Grinder had requested a small, iron-rich object coated in a biocompatible sheath implanted in his finger so that he might reproduce this effect more permanently. It seemed immediately apparent to me that a small high strength magnet would produce much more sensation. My friend Dustin French had already been researching magnet types and sources for implants, and other applications, and was able to quickly get me up to speed on what would probably be best for the applications I had in mind. It had been one of numerous projects sitting on the “to do” shelf for some time when I told my new friend Todd about it. Todd was anxious to start some implant experiments, and was really interested in the magnet idea. I think he appreciated the implications of the sensory experiment a little more than I did, coming from his neuroscience background. In the space of a month or two I ordered in a few different sizes of high strength neodymium-iron-boron magnets and dip or laminate coated them in a number of different configurations. Four of these were immediately implanted into Todd and myself (see also the original article on Todd).

There was some initial apprehension as to what sort of unusual risks we might be taking by installing implants like this. I already had an arm full of Teflon and silicone implant work I had done with Steve, so the idea of getting strange new implants was nothing new to me, but the addition of high strength magnets brought in a completely new and alien factor to the scenario. Many people believe strongly in healing and other physiological effects from having these sorts of magnets in contact with their bodies. So at least from their perspective, putting the same under ones skin might have powerful effects, possibly depending on the location. Todd spent some time searching medical and scientific publications, and didn’t come up with anything significant either for or against the idea. There was study data pointing towards coated neodymium being safe for use, and one study that actually seemed to come to the conclusion that the strong magnetism caused cytoxicity (tissue damage, basically), but after some review of the study and others that pointed to the contrary we decided that the risk was reasonable for us to undertake. Todd’s final conclusion was that the only real physical effect might be some attraction to iron in the blood which would probably aid local circulation and simply result in better healing. This was of course just a guess, but trying to predict how an implanted magnet might affect electromagnetic energy flows in and around the body, and what feasible effect this would impart on the individual is well outside of our personal grasp, or ability to measure. And to some of us, well, just a bit silly. For our first experiment we installed two types of magnetic implants. I got a pair of 1/4 inch diameter 1/16 inch thick binary polarity (one magnet facing N, one S) device attachment units in the side of my wrist. Todd got one of the binary units placed near his elbow in the outside of his forearm, as well as our first sensory unit placed in the pad of his left ring finger. The left ring finger was chosen as the least critical fingertip in case of catastrophic damage. While the pinky finger is smaller and may seem to some to be less significant, its placement as the outside finger means that it performs more critical gripping functions. So to the question, “if you had to lose or seriously damage one of your fingers, which would it be?”, this was our answer. This first sensory unit was a stack of five 1/16 inch diameter 1/32 inch thick gold-plated magnets, dip coated in carefully applied layers of 30 shore RTV (room temperature vulcanizing) silicone to try and get a good solid case without too much unnecessary bulk (I will get into more coating specifics later).

My attachment units had a somewhat eventful healing given that the one closest to my hand was pushed a couple inches out of place on multiple occasions during healing! Pushing it back into place was uncomfortable, but mostly just a bizarre experience for me. Dislocated implants are not terribly uncommon, but I had never had to relocate one on myself. Other than that, the healing was fine. The attachment strength was enough to hold something the size and weight of a wristwatch to the side of my forearm at a reasonable strength, but not so much that it couldn’t be pushed off with a fairly minor impact. The attractive strength was however enough that it became apparent that extended wear of such an attachment would almost certainly cause tissue death in the compressive zone above the implants, and would result in eventual rejection. This left me with the conclusion that magnetic implant device attachment is not terribly viable, and I haven’t pursued the idea much since. I do have extensive plans for magnetically attached eyelenses which may be reasonable if only worn for a few hours at a time, but I haven’t quite been able to justify the risk of damage to my face yet. A couple months after healing my wrist units I had a trip to the East Coast scheduled, and had some real worries about airport security. Neither Todd or myself had been through an airport since we got the units, and had no idea what sort of effect the magnets would have on the security gates. Given that my magnets were immediately adjacent to another enormous group of subdermal implants in my forearm that had enough mass that they might be misconstrued as some sort of totally bizarre concealed weapon, I didn’t want to attract any unnecessary attention to my arm, especially after the recent terrorist hijackings. So we removed my units a week or two before my flight. I was later surprised to hear that Todd’s unit set off nothing at all when he flew a month or so later. In the case of the first sensory unit, from the moment it was installed, it was clear that Todd’s was definitely going to be able to sense strong magnetic fields, but the full extent of the range of sensations was not immediately apparent. A few weeks later when he started to demonstrate his ability to locate power transformers inside electronic casings, and feel magnetic currents traveling through cookware on electrical stovetops, we decided we were going to have to do a lot more with these magnetic sensory units. Todd still has both of the initial experimental implants installed. While the attachment unit near his elbow is relatively non-functional, it makes for great parlor tricks, and as a conversation starter at bars and such with it’s ability to aggressively attract bottlecaps. His sensory unit has been bugging him a little bit lately, and he has been considering removal, but as of now it is still installed.

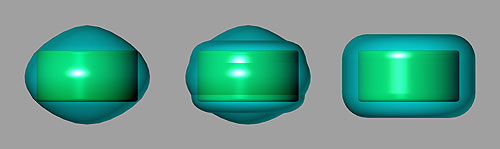

After the success of Todd’s finger implant I decided to make a serious coating device for the magnets. The initial unit had been dip coated and then touched up by hand over the thin corner areas. This approach can be reasonably viable some of the time, but dip coating leaves dangerously thin areas of silicone over outside edges on parts as a result of surface tension. These thin areas can be touched up with additional silicone coats focused on the thin areas, but this approach leaves a lot of room for error and case failure, which has later become apparent in Shannon Larratt’s fingertip units (read that story here). Dip coating also results in a more bulky coating which can easily double the size of the implant at this scale. To solve this problem I designed a pair of two stage manual injection molds that applied a precision case of even thickness to single 1/8 inch diameter 1/16 inch thick, and 1/16 inch diameter 1/32 inch thick neodymium magnets (12 at a time). The design was drawn up in CAD software on computer and then machined on our VMC (vertical machining center).

The mold is manually filled with a small interlocking piston mechanism. This allows for the entire operation to happen inside of a small hooded area for cleanliness. I was able to get a small number of good parts out of the larger size mold before I finally gave up on it. The only intact parts that came out of the smaller one were either dirty (the first shot is always tossed as it picks up any debris that may have been left behind in the cavities after cleaning) or had bubbles. I had one of these good parts installed in my finger by Steve and basically gave up on the molds after that. My friend Amanda spent some weeks trying to get good parts out of the molds for Steve and gave up as well, eventually resorting back to the dip coating method, which has proven over time to be insufficiently stable for the application, unless applied in large volume.

Steve installed a number of the dip coated units on various people, including himself and his girlfriend Cookie. Some units I believe made it into the hands of other artists as well. But the only other units that have been particularly different or any sort of new functional experiment on my front were those installed in Shannon which were aimed at determining the difference between the effectiveness of centralized or dispersed groups of small magnetic units. Unfortunately, he couldn’t discern much of a difference between the two types, and the only conclusion that seems to have come from them at the moment is that the small single dip coated units have a weak case that is prone to failure.

Fingertips are a tricky place to put an implant, while the procedure in this case may be relatively simple, fingertips undergo enormous compressive forces regularly. The pads of your fingers do not function as pads quite as well when they have a hard little knot moving around inside of them. Because of these forces a very resilient sturdy coating is required on the magnet itself, and thin silicone dip coatings appear to fail far too easily. Placement towards the tip of the finger is not advised as the finger tips have too much regular compression in common day to day activities (especially typing). The centerline of the palm side of the finger must also be avoided so that the implant is not impacted into the bone during high force gripping activities. My personal implant has functioned well and remained stable through various types of minor trauma and one serious laceration in close proximity to the implant. I do not do a large amount of typing in my day to day activities, and I am suspicious that this may be a factor in other units that have had more problems. I do however work with my hands a lot doing precision machining and some manual finishing work, but I feel that I am conscious of my implant and instinctively counter for situations where I might crush the implant in an uncomfortable manner. I remember developing this behavior during healing. My implant is one of the larger units produced by my molds, so it does create a fairly palpable mass in my finger tip that can get in the way every once in a while, mostly when lifting heavy objects, but I cannot think of a time that this has actually handicapped me in any way, and I can think of many that it has performed as a utility. In addition to Shannon’s case, failure related removals which are being documented simultaneously to this post, my friend Amanda has had her unit removed from a site similar to mine. Her fingertip became swollen and inflamed in the location of the magnet, likely related to her job where she cleans, operates and handles intricate pieces of metal constantly. My current direction with the technology would be to get the small case mold running and try the smaller units spaced well away from common gripping and impact sites, but other projects require my attention currently, and I may have an entirely different approach and/or coating method in mind by the time I get back to this.

These are dangerous unpredictable experiments, and anyone who takes part does so at thier own risk. I get a lot of people trying to get these implants from me, please don’t bother, I make novel experiments for myself and close friends. Selling you implants would imply some enormous responsibilities on my part, and I’m just not interested in that.

Online presentation copyright © 2006 Shannon Larratt and BMEzine.com. Requests to republish must be confirmed in writing. For bibliographical purposes this article was first published online March 31, 2006 by BMEZINE.COM in Toronto, Ontario, Canada. |