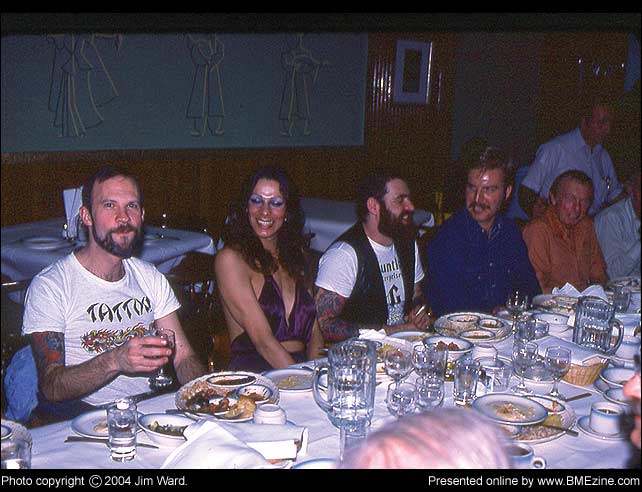

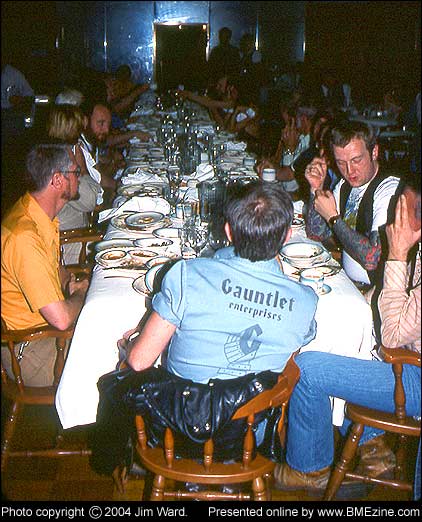

“In the beginning there was Gauntlet” Starting any new business can be challenging especially for someone who’s never done it before. The challenge gets multiplied several times when it’s in a new industry. To the best of my knowledge no one before me had ever attempted to do just body piercing as a profession. A handful of tattooists were doing it, but it was strictly a sideline.It’s not that someone else couldn’t have done what I did. The time just happened to be right, and I was the one who seized the moment. Within a few short years the world had seen the hippie movement, women’s liberation, and gay liberation. The sexual revolution was in full swing. I saw no reason to be ashamed because piercings turned me on and no reason why the rest of the world shouldn’t find out what piercing might have to offer them. I imagine the process of starting a new business is pretty much the same anywhere, but here in California you have to file a fictitious name statement and run a notice in the newspaper to the effect that you’re doing business under that name. Then you need to open a business bank account and do the necessary paperwork with the State Board of Equalization for the privilege of collecting sales tax. Plus there are lots of little odds and ends. It’s pretty much a pain in the ass. But before you can do anything you need a name for your business. Doug and I went back and forth trying to come up with something. He favored a mythological theme such as the name of a Greek god. I wanted something with a tough, masculine feel that would appeal particularly to the gay leathermen and S/M fetishists I perceived as my most likely customer base. In the process of accessorizing my leather wardrobe, I had made a wide leather watchband edged with silver-colored pyramid-shaped studs. While watching television one night I removed my watch and set it on the end table. A short time later I glanced over to see what time it was, and in a flash the name came to me. GAUNTLET! It was everything I wanted the name to be. In addition to being rugged and masculine, it also had metaphoric implications. We have two sayings, “run the gauntlet,” and “throw down the gauntlet,” expressions for the ordeal and the challenge. Didn’t that precisely describe this business venture? I did have momentary second thoughts only because there was already a well-known leather bar in LA called The Gauntlet. But that didn’t seem to be a big problem since I’d be calling my business Gauntlet Enterprises. Doug liked the name as soon as I told him about it. He was, however, of the opinion that I should incorporate. But since he didn’t want to be a stockholder or to have any legal attachments to the business, I opted for a sole proprietorship. It was November, astrologically the time of year Scorpio babies are born. Scorpios are supposed to be highly sexual, so I thought it would be an ideal time for my business to be born. Since the sign ends around the 21st of the month, I needed to act soon. Thus it was that on the 17th of November 1975, I drove to the closest newspaper office, filled out the necessary forms, and filed the fictitious name statement. Gauntlet Enterprises was on its way. There was now a flurry of activity. So many things needed to be seen to: the bank account, sales tax issues, setting up a place to make jewelry, developing jewelry designs, designing a logo… the list went on. Everything seemed to be happening at once. My mental picture of the logo was of a stylized gauntlet forming the letter “G.” It could thus be used alone or combined with the remaining letters of the word. The personal computer was still about a decade in the future. Artists and designers relied for the most part on traditional media to do their work. One of the newer innovations of the time was rub-on letters. Several companies made them, and though the market for them has largely disappeared, you’ll occasionally see them in art supply stores. At one time there were hundreds of fonts available in a variety of type sizes, with perhaps one or two sizes on a sheet. They consisted of a transparent plastic sheet on which an assortment of letters was printed, mirror image, and then coated with a pressure sensitive adhesive. You would place the sheet, sticky side down, on a surface and one by one rub the letters onto it. After spending some time browsing through the catalogs at the art supply store, I found a font that seemed to have the character I was looking for and a letter “G” that had a vaguely open fist shape. The font was called Hondo. I purchased a sheet of larger sized letters. A visit to the public library proved helpful. Browsing through several books with pictures of medieval armor, I found a number of images of gauntlets from which to draw inspiration. Back home I gathered my art materials together and set out to create the logo. After rubbing a capital “G” onto a suitable piece of paper, I took a sheet of tracing paper and a pencil and began to sketch over it, trying various ways of creating a gauntlet from the letter. In time things came together and I had something that looked like it would work. After carefully tracing the design onto the sheet with the rubbed on letter, I used a draftsman’s pen to ink the details. It took several attempts to get things precisely right, but finally, success. To be able to make jewelry I needed a jeweler’s workbench. Commercially made ones were very expensive, and I felt the money could be better spent. Using scrap lumber from construction sites and a piece of plywood from a packing crate, I made my own workbench. It might not have been much to look at, but it was functional and adequate for my needs. That bench was in use till Gauntlet’s demise nearly 25 years later, and by some twist of fate, and the generosity of Josh at Good Art, I still have it today. Here on BME Gauntlet has earned the reputation for being “conservative.” In this forum that is something of a dirty word, usually used with contempt and derision. The same people who are quick to assume that I never took risks often fail to consider what things were like in 1975. Because there was little precedent, everything I did in those days was a risk. No one had ever attempted what I was doing at least on the scale I intended to do it. There was no Internet providing vast informational resources at the tip of one’s fingers. Every piercing technique, every jewelry design, every material used for the jewelry or in the piercing process had to be subjected to a trial and error process. That meant taking risks. Rather than calling me conservative, a better word would be cautious. It was essential to me that every precaution be taken to assure the well being of every person I pierced or who wore my jewelry. What would the fate of the entire piercing movement been if I hadn’t proceeded cautiously and someone had suffered serious harm? How quickly would the movement have come to an abrupt end? Fortunately, starting out with such a small customer base I was able to personally keep tabs on the people I did business with. If something went wrong, I had the opportunity to figure out why and immediately try something different. By proceeding with caution I could progress slowly and minimize the risk of serious harm. Of course, without Doug none of this would have happened. He provided a catalog of “traditional” piercings, along with their often-colorful histories, which leant them credibility and implied that they were all possible. However crude, he had acquired some rudimentary piercing techniques. Over a period of years he also had managed to make contact with about a hundred fellow piercing enthusiasts. Combined these three things provided a foundation on which I could build my infant business. Doug’s motives for setting me up in business were not entirely altruistic. He was married and had four adult children, but his heterosexual life provided no outlet for his piercing fetish or the expression of suppressed gay yearnings. By helping me start a piercing business he was hoping to have the opportunity to fulfill both these needs. Primarily by placing classified ads in various gay and fetish publications, Doug had made contact with a couple of dozen gay men in the LA area who shared his fetish for piercing. As a means of helping get Gauntlet launched, Doug proposed that we start a social group for these men. We would get together once a month for a potluck supper. After eating and socializing anyone who was interested could get pierced with what Doug called “the laying on of hands,” his term for the moral support of the rest of the group. This gave me the opportunity to do piercings under his direction and at the same time bring in a little money from the sale of the jewelry. On occasion we’d all meet at a local restaurant and reconvene at someone’s home afterwards for the piercing event.

Initially Doug proposed calling the group the Society of Saint Sebastian for the saint who was martyred by being shot through with arrows. But that name thankfully never stuck. Instead it ended up just being called the T&P Group, short for tattooing and piercing. Back in my fine art days I’d made some silk screen prints. The skill came in handy for a bit of advertising and promotion. I silk-screened some T-shirts with the Gauntlet name and logo on the front. I also bought a button making device and produced a series of buttons with drawings of various piercings, the Gauntlet logo, and the slogan, “We’ve got what it takes to fill your hole.” We gave these out to the T&P group and to clients who got pierced. Designing and making jewelry for body piercing offered a wide range of challenges. Before Gauntlet most piercing enthusiasts had no choice but to make do with earrings or some makeshift contrivance of twisted wire. Frequently the material was a silver or gold plated mystery metal hardly suitable for the purpose. Earrings were universally too thin. There were some loop style earrings consisting of a fairly thick tube with a thin wire that was intended to go through the piercing. Some hardy individuals managed to work the thicker loop through their piercings, a process that would have been uncomfortable to say the least. There still remained sharp edges which, if the ring rotated, could irritate and cut the tissue. Bent pieces of wire also posed problems. There was virtually no way to provide a closure that would not snag on clothing or on the edges of the piercing itself. From the beginning there was interest in stainless steel as a material for piercing jewelry, primarily because it was perceived as inexpensive and because many men preferred its silver color. Unfortunately I had no knowledge or experience with the material; every piece of jewelry I’d ever made was of gold or silver. Consequently the majority of my early jewelry was made from gold. I did design some pieces of silver, but the portion which went through the piercing was always of gold. Those who insisted on silver colored metal had to settle for white gold. Our knowledge of jewelry materials at the time was quite limited. I had no idea just what effect the unknown components in various gold alloys had on people’s bodies. Even though I was using 14-karat gold, some people still had bad reactions to it. In those cases our only option was to insert monofilament nylon. We had no idea that nickel was a common allergen in alloys. I’m not proud to admit it, but Gauntlet’s first jewelry brochure included a piece of gold plated nickel silver jewelry. Fortunately we quickly realized its incompatibility and discontinued it immediately. The one piece of jewelry that became Gauntlet’s bread and butter was what I called the Bead Ring. It might more accurately have been called a Fixed Bead Ring since the bead that acted as a closure was soldered to one side of the ring’s opening. In recent years the design has largely be supplanted by the Captive Bead Ring in which the bead simply snaps into a gap in the ring. This design is cheaper to manufacture and allows the wearer to choose a vast variety of bead materials. But since my primary focus was always on piercing as a means of sexual enhancement, I always felt the fixed style was a better choice. One never had to worry about losing the bead in the carpet if the activity got a little rough. I can’t claim that the bead ring design was my own. Back when I first pierced my nipples, I had purchased a pair of earrings of that design in a department store. What made them a unique Gauntlet design was the fact that they were scaled in a variety of larger diameters and thicknesses suitable for body wear.

The first barbells I recall came from Germany. Doug had made contact with Tattoo Samy, a tattooist and piercer from Frankfurt. Over the years Samy came to the States a number of times and frequently showed up in LA to visit Doug. On one of his first visits he showed us the barbell studs that he used in some piercings. They were internally threaded, a feature that made so much sense that I immediately set out to recreate them for my own customers. This was a particularly difficult challenge. The biggest problem was how to do the threading. My gold supplier offered 1/16” gold tubing, the equivalent of 14 gauge. This would work as the post, but how could I tap it? I’d also need the right thickness of wire and a suitable die for the male thread. Fortunately, after consulting some technical person, a company that I had purchased jewelry making equipment from was able to provide the tools that I needed. Next I had to find suitable balls for the ends. Initially I used those ear studs that are just a gold ball attached to a post. I cut off the ear post and soldered the ball to the barbell post. This was completely unsatisfactory. First there was an unsightly flange left where the post was attached to the ball. Second, the ball had a tendency to explode when it was heated with a torch. That wasn’t much fun. Lastly, the material was so thin that after it was heated it became so soft it could easily be dented with the thumbnail. This wasn’t something I could sell. What to do? Fortunately fate intervened. On the elevator at the jewelry mart one day I was discussing the problem with a friend. There was another man on the elevator with us who overheard the conversation and gave me the name of a findings company where I’d be able to purchase “no-hole” balls that would meet my needs. The lead proved invaluable, and for many years Gauntlet purchased balls from them for a number of our jewelry designs. Piercing techniques provided their own unique challenge. Thus far I’d followed Doug’s lead, and aside from the occasional fumble, things were progressing fairly well.

As role models for issues of sterility and hygiene we turned primarily to some of the more responsible tattooists of the time, especially Cliff Raven who had recently moved from Chicago and opened a shop in West Hollywood. Autoclaving instruments after each use was a given. But the use of latex gloves didn’t occur until the AIDS epidemic hit nearly 10 years hence. Our rationale at the time was that even dentists weren’t using them and doctors only used them for surgery or for probing in a patient’s private orifices. For some time we continued to use the ear-piercing gun to do nipples. This limited us to using only 16 gauge, pretty thin by today’s standards, but certainly thicker than the earrings everyone was used to. On occasion I encountered nipples that were on the tough side, but with a little extra muscle I always managed to get the piercing point to go through. Then came the day that forever changed this technique. Doug called me up and told me that some guy who’d answered his classified ad wanted his nipples pierced. We arranged a day and time to go to the guy’s apartment where I would do the piercings. Everything was going smoothly until the actual piercing. The point of the ear piercer scarcely penetrated the skin; it wouldn’t go through. I could feel myself sweating partly from embarrassment, partly because I knew the guy was very uncomfortable. With every bit of strength I could muster, I made one final attempt to get the point to do its work. However, instead of going through, it bent. At this point I realized that the ear piercer was not the best tool for piercing nipples since there was no way to tell how tough they were going to be. By now I was soaking wet. Though uncomfortable, the client was bearing up incredibly well and was determined to persevere until he had the piercings. Doing my best to save face and keep the client calm, I quietly reassured him everything would be fine, set the ear piercer aside, and had Doug get me a cork and one of the large hypodermic needles from the piercing kit. The nipple was still in the forceps. I placed the cork on one side and, placing the needle in position on the other, thrust it through the nipple into the cork. Though the going was still a bit rough, the nipple yielded. I now encountered other problems. The forceps couldn’t be completely removed. I was able to open them and free them on the point end of the needle, but the syringe coupling was too large to pass through the remaining opening. I’d just have to work around them. It was also going to be tricky inserting the jewelry because the point of the needle was beveled. Fortunately we were inserting nipple retainers that had a straight post, so they managed to follow through without too much difficulty. At the time I simply attributed all the fumbling and difficulties to my own lack of experience. This was partly true, but the tools themselves were actually a much more significant factor. This was about to be demonstrated most dramatically as I undertook my first Prince Albert piercing.

Doug’s technique for doing this piercing was incredibly difficult. A small dab of topical anesthetic was placed on the end of a cotton swab (one with a wooden stick) and the swab inserted about an inch into the urethra. After waiting about ten minutes for the anesthetic to penetrate, it was time to do the piercing. The piercer would grip the cotton swab, position its tip just beneath the place where the piercing would go, and, with a hypodermic needle of suitable thickness, pierce into the tip of the swab. In order not to puncture the inside of the urethra, the needle and swab needed to be kept securely together until the needle was outside of it. Any piercer who hasn’t done this has no idea just how hard it is. Unless their grip is just right, the tissue can move around and the needle miss its mark. In time I mastered this technique and eventually figured out a better method, but at the time it was like trying to hit a moving target behind a curtain. Somehow I managed to actually do the piercing. It was now time to insert the jewelry, a 14-gauge bead ring. I had to attempt to get a circular object to follow a straight one with a beveled point. This wasn’t working well. Once again I was sweating profusely and beginning to panic. Things were getting bloody. More by shear force than anything else, I managed to get the ring in. Although the piercee was an incredibly good sport about it all, I felt terribly embarrassed. I knew that this method was too crude. Guys who had been around the S/M scene might easily take it in stride, but I couldn’t expect that of others.

It was then that I had one of my “Eureka!” moments. If I simply cut the syringe coupling off the needle, I would then be able to follow it through with the jewelry. In that instant one of the revolutions in piercing technique took place. From then on at least one hurdle in the piercing process had been conquered. Next: Who Was Doug Malloy? — part 1

|

||||||||||||||||

Post navigation

BME/News and Modblog highlight only a small fraction of what BME has to offer. Take our free tour and subscribe to BME for access to over 3 million body modification related photos, videos, and stories.

BME/News and Modblog highlight only a small fraction of what BME has to offer. Take our free tour and subscribe to BME for access to over 3 million body modification related photos, videos, and stories.